I’m feeling guilty. Not (for once) because of the gap between posts, but because of a decision I have recently made. I’ve had enough. A straw has broken this camel’s back. Well, not so much a straw as chunks of gorse, miscellaneous pieces of dried vegetable matter, things I believe to be dried sheep shit, and – ergh – scurf. Lots and lots of scurf. Did I mention scurf?

It’s not the fault of sheep. I still like sheep, don’t get me wrong.

Let me explain. I’ve been an advocate here, repeatedly, and elsewhere, also repeatedly, for the use of fleeces in spinning. And particularly local fleeces. I have waxed lyrical on the subject of wool miles. I have been and chosen fleeces on the hoof. Hoof? Well, yes:

I’ll have that one, and that one, and how about that one? When they’re sheared, in six months… I’ve visited farms, learned about how one sheep ate the stock book, how another chased tourists begging for sandwiches, how another taught all her lambs how to squeeze under the gate on the lane by apparently making themselves two-dimensional. I always had respect for sheep (having early acquaintance with a feisty Scottish Blackface x Suffolk flock helped), and I have developed a deep respect for the history of their long association with humans. That hasn’t changed.

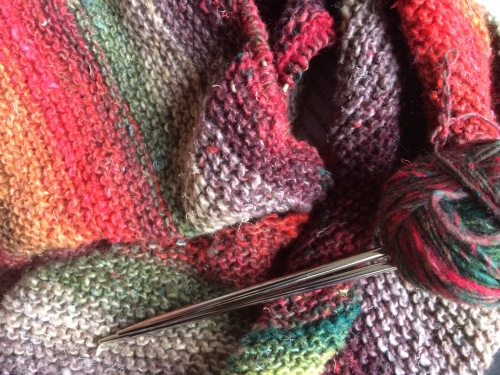

What has changed is the amount of time I am prepared to devote to this:

The appearance of flexible garden thugs – er, trugs, thank you, autocarrot – made an immense difference to my fleece washing days, but still… ergh. And there’s time and energy to be considered. Lots of both. Time, energy and a huge amount of splashing of sheep-shit-diluted water, that is.

And then there’s this:

The drying stage. Again, helped enormously by the purchase of two sweater-drying racks from eBay, and immeasurably by sunshine and a certain amount of wind. This is Wales. West Wales. Wind is not usually a problem… sunshine? Well, that depends.

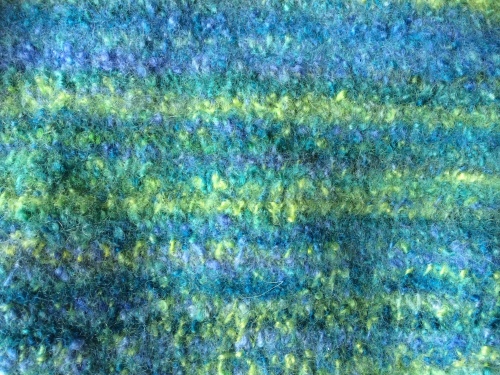

But, if I ended up with something like this:

a Teeswater, otherwise known as the Golden Fleece, or this,

I was well pleased, and I still would be. However…

Sometimes I did not. Sometimes I ended up with a fleece which still had a lot of gorse, bracken, or moss. Fair enough, some of that’s my fault or a dodgy choice of fleece, and it largely comes out in the carding anyway. But that, recently, has not been the end of it. Every single fleece I have recently processed has been scurfy and full of second cuts. One – this should probably be behind a spoiler for the faint of heart and/or easily nauseated – was full of dead fleas. Bugs. Dead whatevers.

OK, free fleeces are always a risk. I learned that early on in my spinning career, with the free Zwartbles of Doom. Zwartbles have dark fleeces. This was was liberally sprinkled with white, quite a lot of which fell on the floor when I unrolled it. In fact, given just how much ended up decorating the floor, that fleece should have been clear. It was not. Scurf. Sheep dandruff. Compost bin. And the last few fleeces I’ve been working with harked back to this unpleasant start. Even though they’d not been free.

I recently pulled out a Jacob’s fleece I’d bought. Gigantic, nice and local, beautifully coloured, and I’d split the fleece into colours when I processed it. Should have looked more closely. This time the problem was lots of short second cuts (SUCH a badly-sheared fleece), and noils. These, for the uninitiated, are very, very short bits of fibre, tangled into small lumps. Sometimes they’re the result of bad carding, but this fleece hadn’t yet been carded – so they were down to weakness in the fleece. A ‘tender’ fleece.

I began working on it.

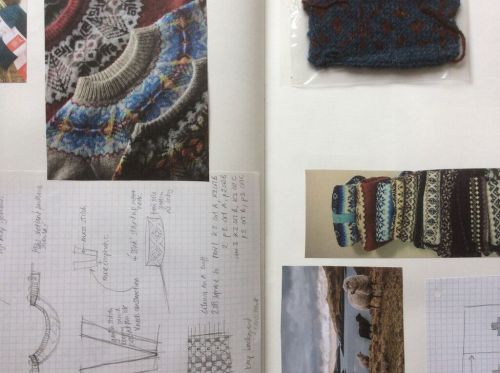

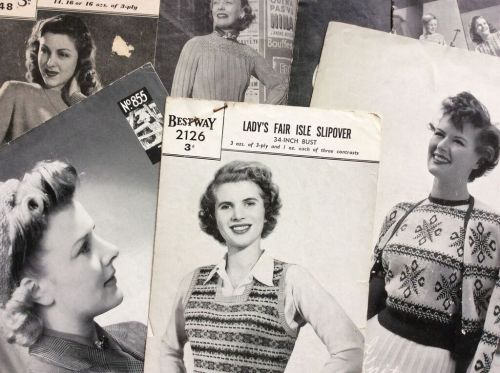

Gently. Sorting it, discarding the worst bits. Carding it, flicking noils out on the carder with a double-ended needle, and hoping most of the short cuts would fall out. (Many did – the mountain of crap accumulating underneath the carder was unbelievable.) I plugged on, determined to get some useable yarn out of this fleece. I’d paid good money for it, I knew its provenance, it was local, I was going to have enough for a jumper because it was just so huge. A colourwork jumper, given how careful I had been about keeping the differently coloured parts of the fleece separate.

No, I wasn’t.

I might get a hat. A smallish hat.

That’s it. That’s all that was useable. It will improve with washing, but it sure as hell won’t increase in quantity.

And that is most definitely it. Producing this small amount took a ridiculous amount of time, a hell of a lot of energy, and almost all the interesting swear words I could make up.

So from now on I am going to be buying roving. Single breed undyed roving is comparatively easy to find, and not that expensive. Not at all expensive when you consider the time, energy, scurf, bracken, spines of gorse and need to invent expressions like pissdongle, flangewhacker and spadwallet. Dear sheep, I still love your fleeces. Honestly, I do. But, in the balancing wool miles against the keeping-my-sanity stakes, I’m coming down on the side of sanity. Or what passes for it.

(And it’s not just sheep. Alpaca. Mites. Ergh.)

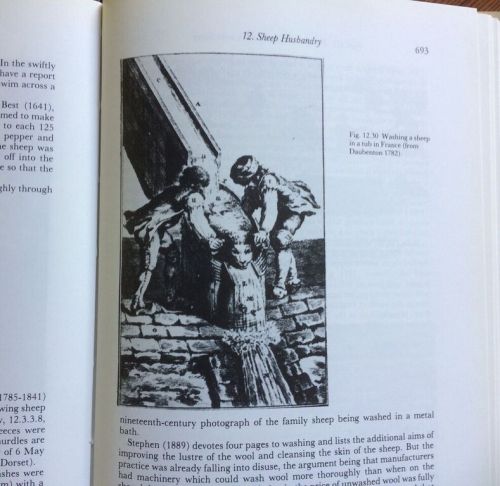

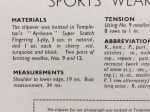

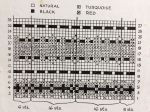

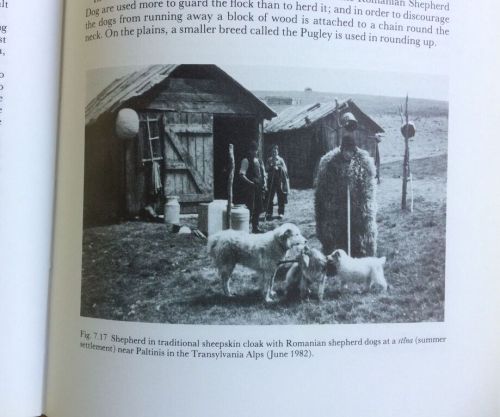

Some time ago I was beyond chuffed to have found a copy of M L Ryder’s huge tome Sheep and Man (I know, I know, but it was published in 1983 when you could get away with that sort of thing – when nobody even questioned it, much of the time).

Some time ago I was beyond chuffed to have found a copy of M L Ryder’s huge tome Sheep and Man (I know, I know, but it was published in 1983 when you could get away with that sort of thing – when nobody even questioned it, much of the time). They did in 1982, when this photograph was taken.

They did in 1982, when this photograph was taken.